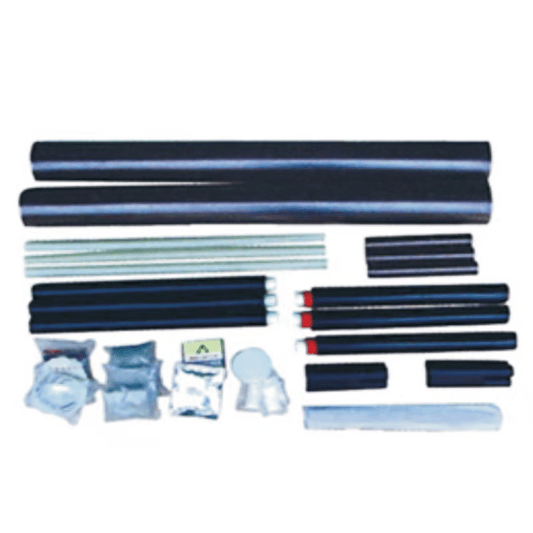

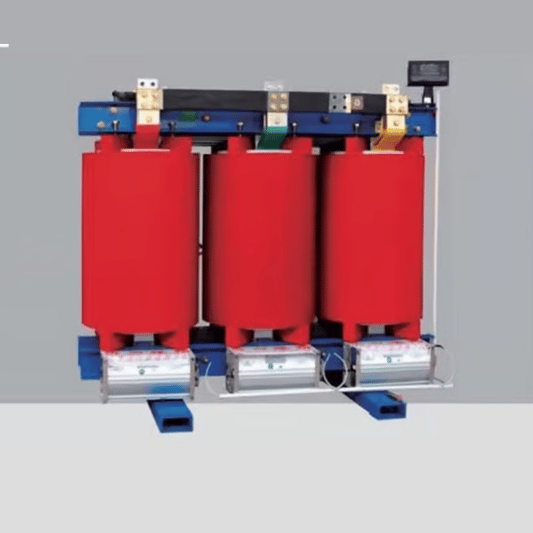

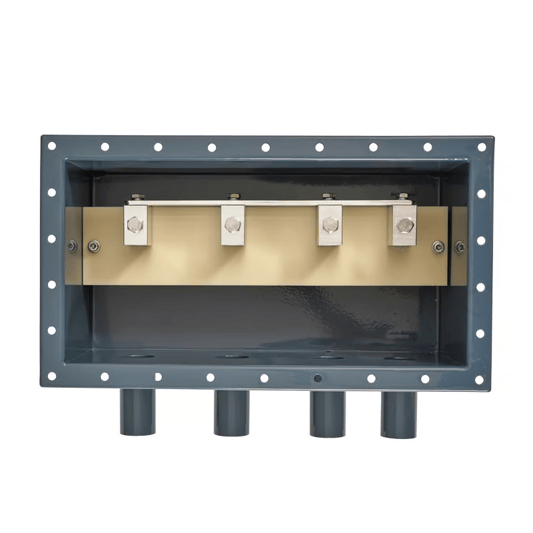

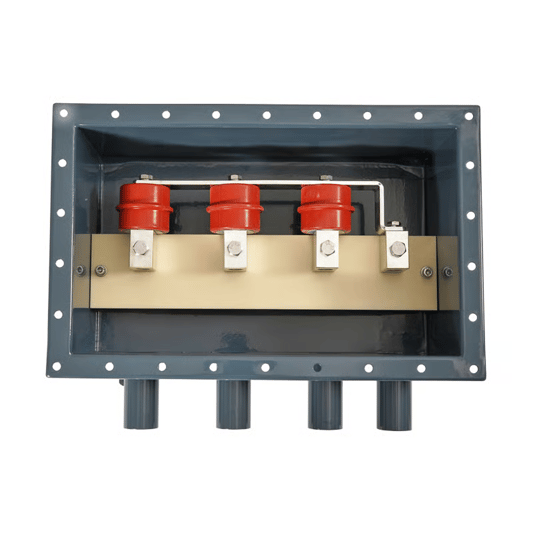

Ensuring Safety with Busbar-bar protective casing Busbars are essential components in electrical systems, used to distribute power efficiently. It is crucial to protect these busbars with a protective casing to ensure the safety and longevity of the electrical system. Types of Busbar-bar Protective Casing There are several types of protective casings available for busbars, including PVC, fiberglass, and polymer casings. Each type offers different levels of protection against factors such as heat, moisture, and mechanical impact. Benefits of Using Busbar-bar Protective Casing By using protective casings for busbars, you can prevent accidental electrical shocks, fires, and short circuits. It also helps in maintaining the efficiency of the electrical system by reducing the risk of damage to the busbars. Installation Process of Busbar-bar Protective Casing The installation of protective casings for busbars is a crucial step in ensuring the safety of the electrical system. Proper installation techniques must be followed to ensure that the casing provides adequate protection to the busbars. Factors to Consider When Choosing Busbar-bar Protective Casing When selecting a protective casing for busbars, factors such as the operating environment, temperature range, and electrical requirements must be taken into consideration. Choosing the right casing ensures maximum protection for the busbars. Maintenance of Busbar-bar Protective Casing Regular maintenance of the protective casing is essential to ensure its effectiveness over time. Inspecting for any signs of wear and tear, corrosion, or damage can help prevent potential hazards and ensure the continued protection of the busbars. Cost-Effectiveness of Busbar-bar Protective Casing Investing in quality protective casing for busbars may require an initial cost, but the long-term benefits far outweigh the expenses. It helps in avoiding costly repairs and replacements due to damage caused by external factors. Best Practices for Busbar-bar Protective Casing Usage Following best practices in the selection, installation, and maintenance of protective casings for busbars can contribute to the overall safety and efficiency of the electrical system. It is essential to adhere to industry standards and guidelines. Industry Applications of Busbar-bar Protective Casing Busbar-bar protective casing is used in various industries, including manufacturing, power generation, and telecommunications. It plays a critical role in ensuring the reliable and safe operation of electrical systems in these sectors. Conclusion In conclusion, busbar-bar protective casing is a crucial component in maintaining the safety and efficiency of electrical systems. By choosing the right type of casing, following proper installation techniques, and conducting regular maintenance, you can ensure the protection and longevity of busbars in your electrical system. Quote InquiryContact us!