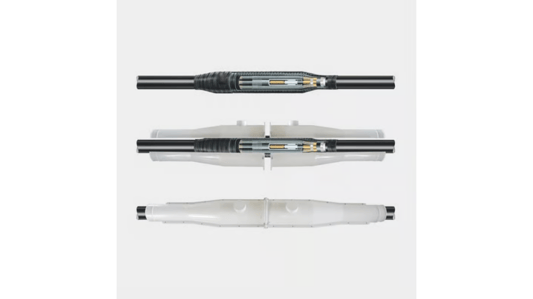

Introduction to Environmentally-Friendly Cable Sealants The growing environmental concerns have driven industries to adopt sustainable materials. One such innovation is the Environmentally-friendly cable sealant of aluminum foil packing. This advanced sealing solution not only protects cables efficiently but also minimizes ecological impact, making it an ideal choice for eco-conscious manufacturers and consumers alike.Material Composition and Sustainability Benefits The core of this sealant lies in aluminum foil packing, a recyclable and lightweight material. Unlike traditional sealants that often involve non-recyclable plastics, aluminum foil packing ensures reduced landfill waste. Its recyclability greatly contributes to lowering the carbon footprint associated with cable manufacturing and packaging processes.Durability and Protection Offered by Aluminum Foil Packing Despite its lightweight nature, aluminum foil packing delivers exceptional durability, providing superior protection against moisture, dust, and mechanical damage. This ensures that cables maintain their integrity over long periods, prolonging usability and reducing replacement rates, which benefits environmental sustainability by curbing resource consumption.Thermal and Electrical Insulation Properties The aluminum foil in the sealant offers excellent thermal resistance, protecting cables from overheating. Moreover, it provides effective electromagnetic interference (EMI) shielding. These properties enhance cable performance and reliability, ensuring safety and efficiency in electrical applications while promoting longer cable lifespans.Eco-Friendly Manufacturing Practices Production of the environmentally-friendly cable sealant of aluminum foil packing integrates green manufacturing processes. Factories utilize energy-efficient technologies and reduce hazardous emissions, aligning with environmental standards and reducing the overall environmental footprint throughout the product lifecycle.Reduction of Harmful Chemicals and Toxicity This innovative sealant minimizes the use of harmful chemicals often found in traditional sealing agents. Aluminum foil packing is free from toxic additives, making it safer for both workers during installation and end-users. Reduced chemical presence also mitigates soil and water contamination risks during disposal.Cost-Effectiveness and Lifecycle Analysis Though initially more costly than conventional sealants, the environmentally-friendly cable sealant of aluminum foil packing proves cost-effective in the long run. Through prolonged cable durability, decreased maintenance needs, and recyclability, the overall lifecycle costs diminish. This financial benefit encourages adoption in large-scale projects and industries.Application Flexibility Across Industries This sealant’s design suits diverse industries including telecommunications, automotive, construction, and electronics. Its eco-friendly nature combined with strong sealing performance supports the growing demand for green infrastructure and sustainable product development across multiple sectors.Regulatory Compliance and Environmental Certifications Aluminum foil packing sealants comply with international environmental regulations such as RoHS and REACH. Furthermore, many products hold eco-certifications that verify their sustainability claims. This ensures that companies using these sealants meet stringent environmental and safety standards globally.Future Trends and Innovations in Eco-friendly Cable Sealants Technological advancements continue to improve the environmentally-friendly cable sealant of aluminum foil packing, focusing on enhancing biodegradability and recyclability. Ongoing research explores integrating nanotechnology and bio-based materials to elevate sealant performance while maintaining environmental responsibility.Conclusion: Driving Sustainability with Aluminum Foil Cable Sealants Adopting the environmentally-friendly cable sealant of aluminum foil packing is a critical step toward sustainable industrial practices. Its blend of durability, protection, eco-conscious manufacturing, and regulatory compliance positions it as a forward-thinking solution that supports global environmental goals while maintaining high-performance standards.Quote Inquirycontact us