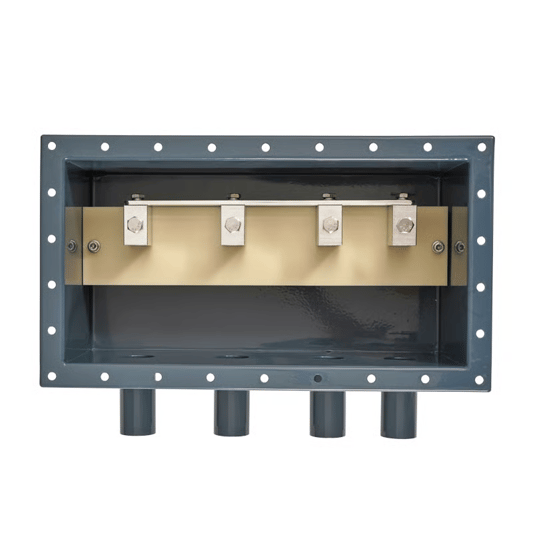

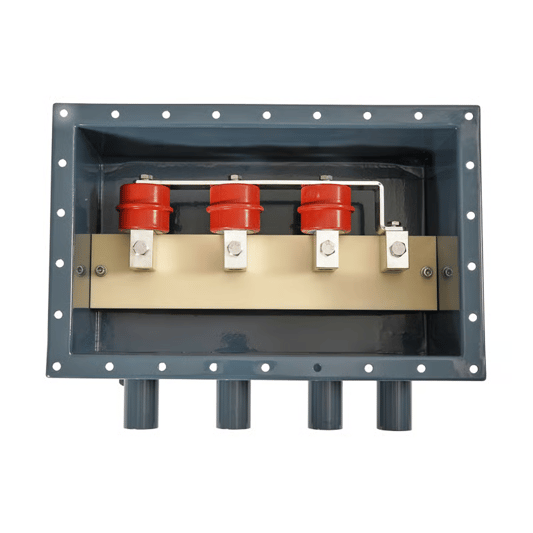

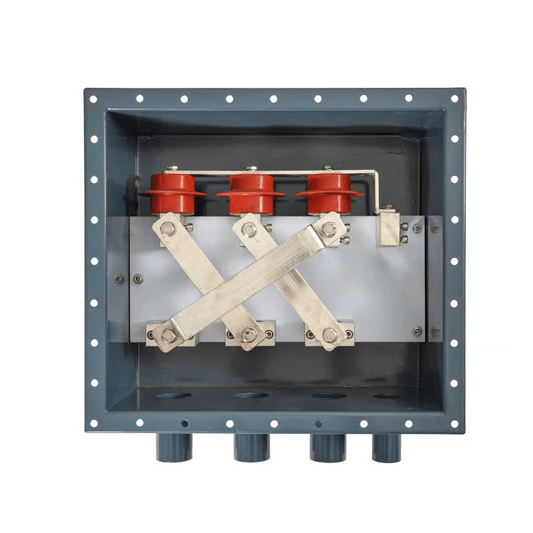

What is a Direct grounding box?A direct grounding box is a vital component used in electrical systems to provide a safe path for electrical currents to flow into the ground. It helps prevent electrical shocks and protects equipment from damage during power surges or lightning strikes.Importance of Proper GroundingProper grounding is essential in any electrical system to ensure the safety of individuals and the longevity of equipment. Without a direct grounding box, electrical currents may flow unpredictably, leading to potential hazards and malfunctions.Benefits of Using a Direct Grounding BoxBy utilizing a direct grounding box, you can effectively disperse excess electrical charges, prevent static buildup, and minimize the risk of electrical fires. This simple yet essential component offers peace of mind and enhances the overall safety of your electrical system.Types of Direct Grounding BoxesThere are various types of direct grounding boxes available, including rod grounding systems, plate grounding systems, and buried grounding systems. Each type serves a specific purpose and can be customized to suit the needs of different applications.Installation of a Direct Grounding BoxProper installation of a direct grounding box is crucial to ensure its effectiveness. It is recommended to consult with a professional electrician or technician to determine the most suitable location and method for installing the grounding box.Maintaining a Direct Grounding BoxRegular maintenance of a direct grounding box is essential to ensure its functionality. Inspections should be conducted periodically to check for any signs of wear or damage, and necessary repairs or replacements should be carried out promptly.Common Issues with Direct Grounding BoxesSome common issues that may arise with direct grounding boxes include corrosion, loose connections, and inadequate grounding. It is important to address these issues promptly to maintain the integrity and effectiveness of the grounding system.Enhancing Safety with a Direct Grounding BoxIn addition to providing a safe path for electrical currents, a direct grounding box can also enhance overall safety by reducing the risk of electric shocks, equipment damage, and fire hazards. It is an essential component for any electrical system.Regulations and Standards for Direct Grounding BoxesThere are specific regulations and standards set by governing bodies that dictate the requirements for direct grounding boxes in different industries. It is important to ensure compliance with these standards to guarantee optimal safety and functionality.ConclusionIn conclusion, a direct grounding box plays a crucial role in maintaining the safety and efficiency of electrical systems. By understanding its importance, benefits, and proper installation and maintenance practices, you can ensure a reliable and secure electrical infrastructure.Quote InquiryContact us!