Intermediate joints are connections used in construction to join structural members together. These joints are essential for transferring loads from one member to another, ensuring the stability and integrity of the overall structure.

Types of Intermediate Joints

There are various types of intermediate joints, including butt joints, lap joints, and T-joints. Each type serves a different purpose and is used based on the specific requirements of the construction project.

Importance of Intermediate Joints

Intermediate joints play a crucial role in distributing loads evenly across structural members, reducing stress concentrations, and preventing failures. Understanding how to design and install intermediate joints correctly is essential for ensuring the longevity and safety of a building.

Materials Used in Intermediate Joints

Different materials can be used in intermediate joints, including steel, wood, and concrete. The choice of material depends on factors such as the load-bearing capacity required and the environmental conditions the structure will be exposed to.

Design Considerations for Intermediate Joints

When designing intermediate joints, factors such as the type of load, the strength of the materials, and the overall structural stability must be taken into account. Failure to consider these factors can result in joint failure and compromise the structural integrity of the building.

Common Issues with Intermediate Joints

Some common issues that can arise with intermediate joints include improper installation, inadequate reinforcement, and material fatigue. Regular inspection and maintenance of these joints are essential to prevent these problems and ensure the safety of the structure.

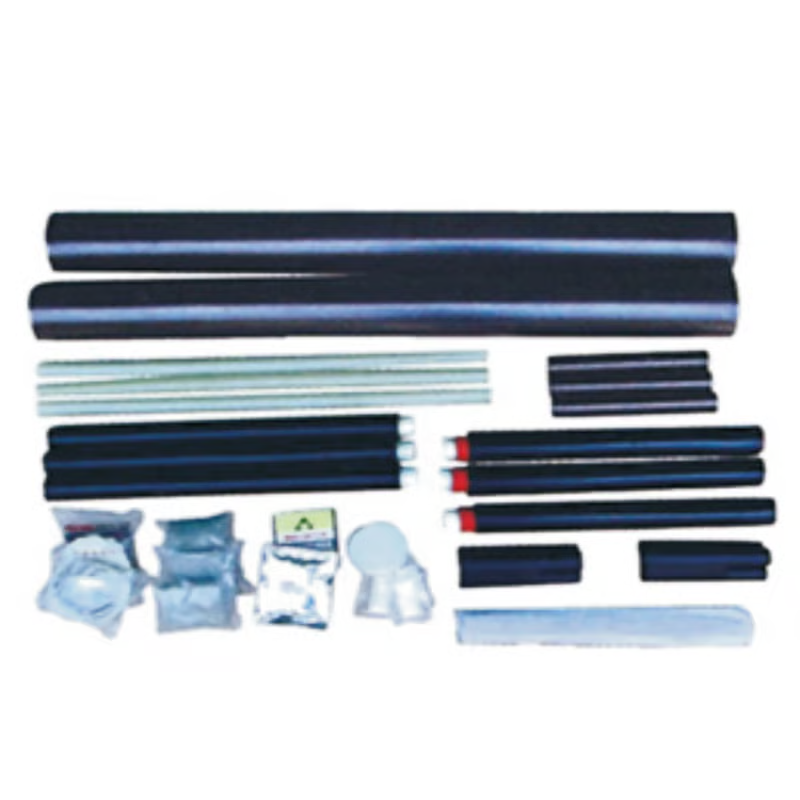

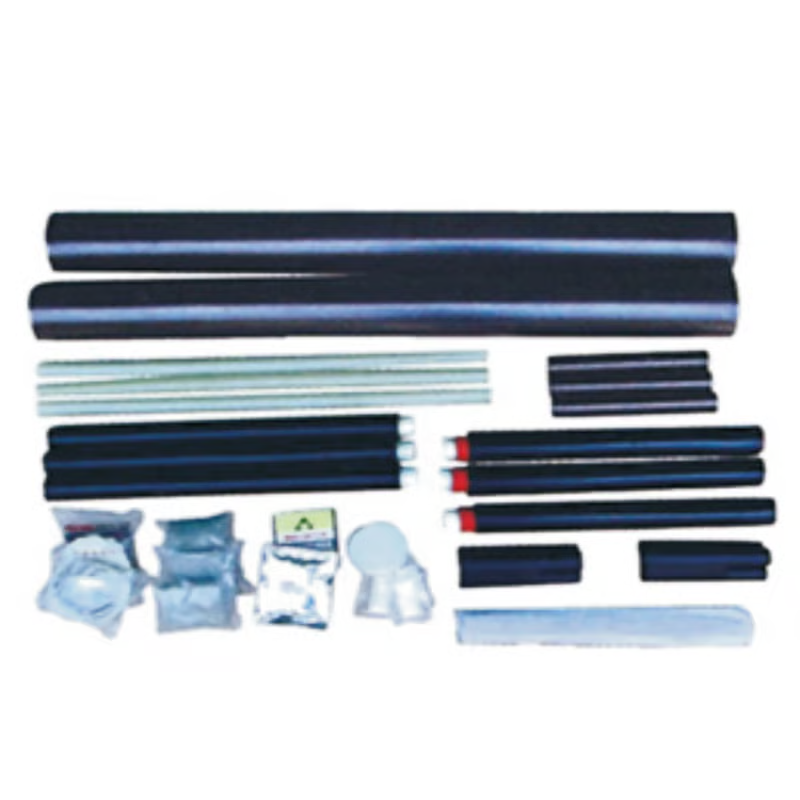

Best Practices for Installing Intermediate Joints

Proper installation of intermediate joints is crucial for their effectiveness. This involves following manufacturer guidelines, using the right tools and equipment, and ensuring that the joints are securely in place.

Future Trends in Intermediate Joints

With advancements in construction technology, new materials and techniques for creating intermediate joints are constantly being developed. These innovations aim to improve the strength, durability, and efficiency of these joints in construction projects.

Training and Education for Intermediate Joints

Understanding how intermediate joints work and knowing how to install them properly requires training and education. Construction workers and engineers must stay up-to-date on the latest techniques and best practices for creating effective intermediate joints.

Conclusion

In conclusion, intermediate joints play a vital role in the construction industry by connecting structural members and ensuring the stability of buildings. By understanding the different types of intermediate joints, their importance, and how to install them correctly, professionals can create safe and durable structures that withstand the test of time.

Quote Inquiry

Contact us!