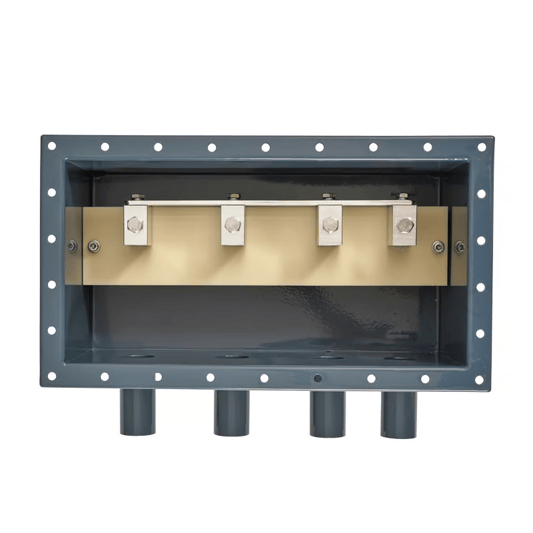

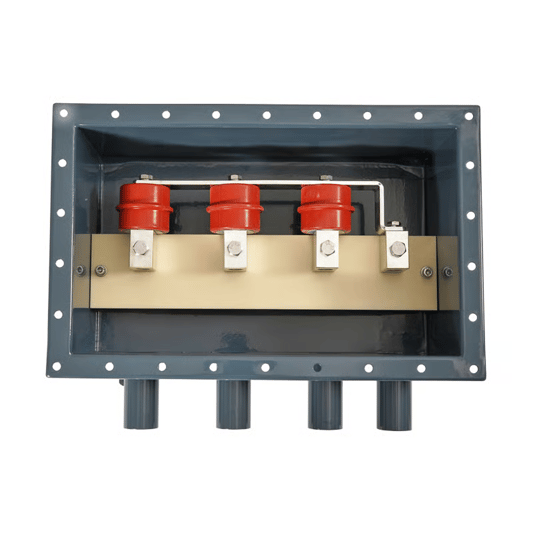

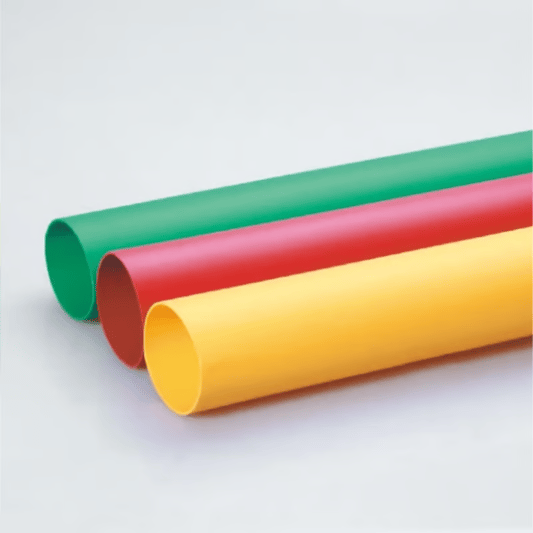

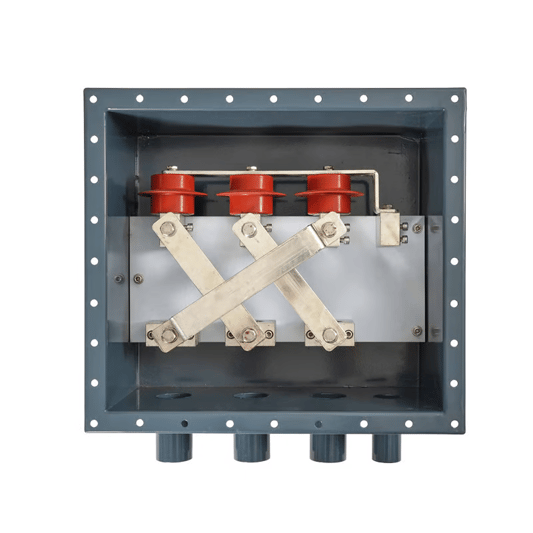

What is Outdoor termination?Outdoor termination refers to the process of terminating cables or wires in outdoor environments to ensure proper connections and protection against the elements. This is a crucial step in the installation and maintenance of outdoor electrical systems, as it helps prevent damage and ensures optimal performance.Types of Outdoor TerminationThere are several types of outdoor termination methods available, including heat shrink terminations, cold shrink terminations, and push-on terminations. Each type has its own advantages and is chosen based on the specific requirements of the outdoor installation.Benefits of Outdoor TerminationOutdoor termination provides several benefits, such as ensuring a secure and reliable connection, protecting cables from moisture and other environmental factors, and extending the lifespan of the equipment. It also helps in maintaining the overall integrity of the electrical system.Importance of Proper InstallationProper installation of outdoor termination is crucial to the overall performance and safety of the electrical system. It is essential to follow manufacturer guidelines and industry best practices to ensure a successful and durable termination.Common Outdoor Termination ChallengesDespite its importance, outdoor termination can pose several challenges, such as exposure to extreme weather conditions, UV radiation, and potential damage from wildlife. Understanding these challenges is essential in addressing them effectively.Key Components of Outdoor TerminationOutdoor termination typically includes components such as cable glands, connectors, insulating materials, and sealing compounds. These components play a vital role in ensuring a secure and reliable termination in outdoor environments.Best Practices for Outdoor TerminationTo achieve a successful outdoor termination, it is important to follow best practices such as proper cable preparation, ensuring cable compatibility with termination materials, conducting thorough inspections, and performing regular maintenance.Applications of Outdoor TerminationOutdoor termination is commonly used in various applications, including power distribution systems, telecommunications networks, renewable energy installations, and outdoor lighting systems. It is essential for ensuring safe and reliable operation in these environments.Choosing the Right Outdoor Termination SolutionWhen selecting an outdoor termination solution, it is important to consider factors such as the environmental conditions, cable type, voltage rating, and installation requirements. Consulting with an experienced professional can help in choosing the right solution for your specific needs.Future Trends in Outdoor TerminationWith advancements in materials and technology, the future of outdoor termination is likely to see innovations in higher performance materials, more efficient installation methods, and enhanced durability. Staying updated on these trends can help in improving outdoor termination practices.Quote InquiryContact us!