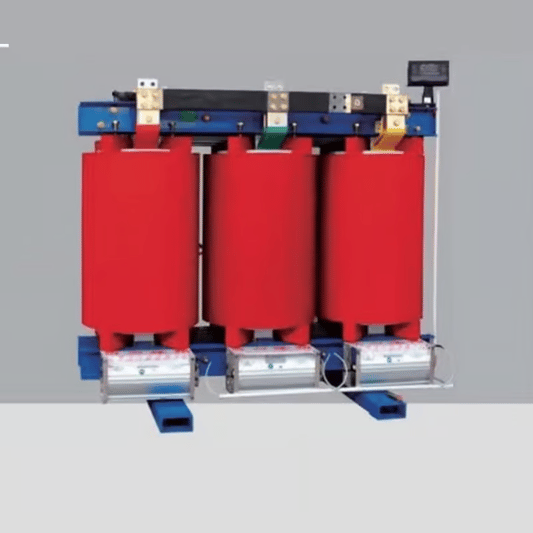

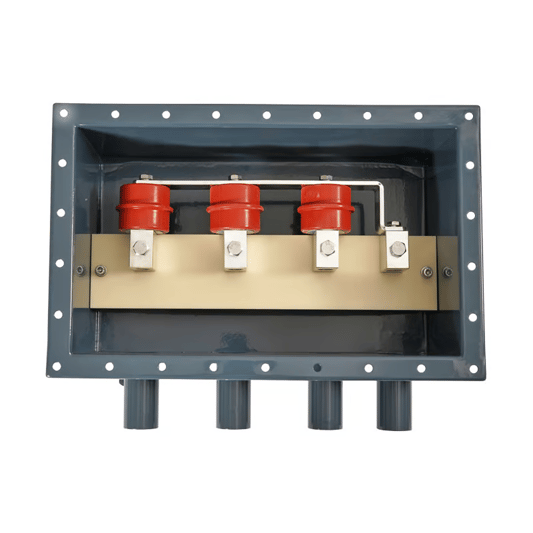

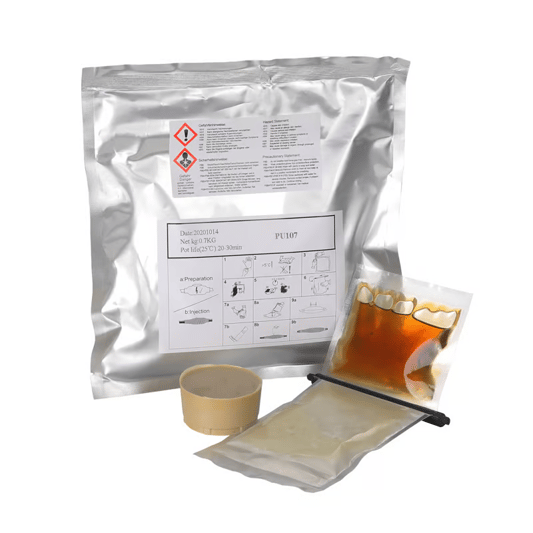

Choosing an Environmentally-Friendly Cable Polyurethane SealantThere are many different factors to consider when choosing a sealant for cables, wires, and other electronic components. One of the most important considerations is the environmental impact of the sealant. Fortunately, there are many options available for environmentally-friendly cable polyurethane sealants, which can provide effective protection for different kinds of voltage. Here are ten key factors to keep in mind when selecting an environmentally-friendly cable polyurethane sealant.1. Low VOCsOne of the most important aspects of an environmentally-friendly cable polyurethane sealant is that it should have low VOCs, or volatile organic compounds. VOCs can be harmful to human health and the environment, so it's important to choose a sealant that has been specifically formulated to minimize their presence.2. High Dielectric StrengthThe dielectric strength of a cable polyurethane sealant refers to its ability to resist electrical breakdown under voltage stress. This is an essential characteristic for any sealant used in electronic applications, as it ensures that the sealant will not break down and cause failure in the component being protected.3. Excellent AdhesionThe sealant must be able to adhere to the surface of the component being protected to provide effective protection and avoid damage. This is especially important in harsh or outdoor environments, where the sealant may be exposed to extreme temperatures, moisture, and other environmental stressors.4. Chemical ResistanceThe cable polyurethane sealant must be able to resist exposure to a wide range of chemicals, including solvents, oils, and other substances that can cause damage to the electronic component being protected. This will help to ensure that the protected component remains functional and safely operational for its expected lifespan.5. Resistant to UV RadiationIn outdoor applications, the cable polyurethane sealant may be exposed to UV radiation from the sun. Sealants that are not resistant to UV radiation can break down or deteriorate, which can lead to damage to the electronic component being protected. Choose a sealant that is specifically formulated to resist UV radiation and maintain its integrity over time.6. FlexibilityAn environmentally-friendly cable polyurethane sealant must be able to flex and move with the component being protected, as well as accommodate any thermal expansion or contraction that may occur. This will help to prevent cracking or other damage to the sealant itself, as well as the component being protected.7. Easy ApplicationChoose a cable polyurethane sealant that is easy to apply, especially if it will be used in high-volume applications or for complex components. Ideally, the sealant should be able to be applied using a variety of techniques, including spraying, brushing, or dipping.8. Compatibility with Different Types of VoltageThe cable polyurethane sealant should be compatible with a wide range of different voltages and electrical applications. This ensures that it can provide effective protection in a variety of different contexts, and can be easily adapted to specific needs or applications.9. Low FlammabilityIn some electronic applications, there may be a risk of fire or combustion. Choose a cable polyurethane sealant that has been specifically formulated to be low-flammability, and that will not contribute to or exacerbate any existing fire risk.10. Long-Term DurabilityFinally, it's important to choose an environmentally-friendly cable polyurethane sealant that provides effective protection over the long-term. This means choosing a sealant that has been designed for durability and that can maintain its protective properties even in harsh or challenging environments.Quote InquiryContact us!