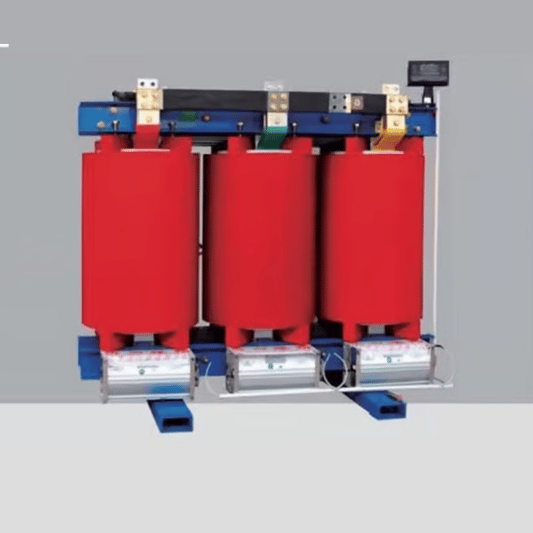

What is an Oil-immersed transformer? An oil-immersed transformer is a type of transformer that is immersed in a special type of oil for cooling and insulation purposes. It is commonly used in the power distribution industry to step up or step down voltage levels. How Does an Oil-Immersed Transformer Work? Oil-immersed transformers work by passing electricity through coils of wire to create a magnetic field. The oil helps to cool the transformer and provides insulation to prevent electrical faults. Advantages of Using Oil-Immersed Transformers Oil-immersed transformers offer several advantages, including efficient cooling, high insulation properties, and durability. They are also relatively easy to maintain and have a long operational life. Applications of Oil-Immersed Transformers Oil-immersed transformers are commonly used in power plants, substations, industrial facilities, and commercial buildings to regulate and distribute electrical power effectively. Types of Oil Used in Oil-Immersed Transformers Mineral oil is the most common type of oil used in oil-immersed transformers. Other types of oil, such as silicone oil and vegetable oil, are also used in certain applications based on specific requirements. Key Components of an Oil-Immersed Transformer The key components of an oil-immersed transformer include the core, winding, insulating oil, tank, and cooling system. Each component plays a crucial role in the efficient operation of the transformer. Maintenance and Testing of Oil-Immersed Transformers Regular maintenance and testing of oil-immersed transformers are essential to ensure optimal performance and prevent breakdowns. This includes oil analysis, insulation resistance tests, and visual inspections. Efficiency and Energy Savings with Oil-Immersed Transformers Oil-immersed transformers are known for their high efficiency levels, which help in reducing energy losses during power transmission. This leads to energy savings and lower operating costs for users. Environmental Impact of Oil-Immersed Transformers While oil-immersed transformers are efficient and reliable, there are concerns about the environmental impact of the oil used in these transformers. Proper disposal and recycling of the oil are essential to minimize environmental damage. Future Trends in Oil-Immersed Transformers With advancements in technology, the future of oil-immersed transformers may see improvements in efficiency, insulation, and eco-friendliness. Innovations such as biodegradable oils and smart grid integration are expected to shape the industry.Quote InquiryContact us!