We offer OEM/ODM service and prioritize delivering high-quality products in a timely manner. Join us as our partner today!

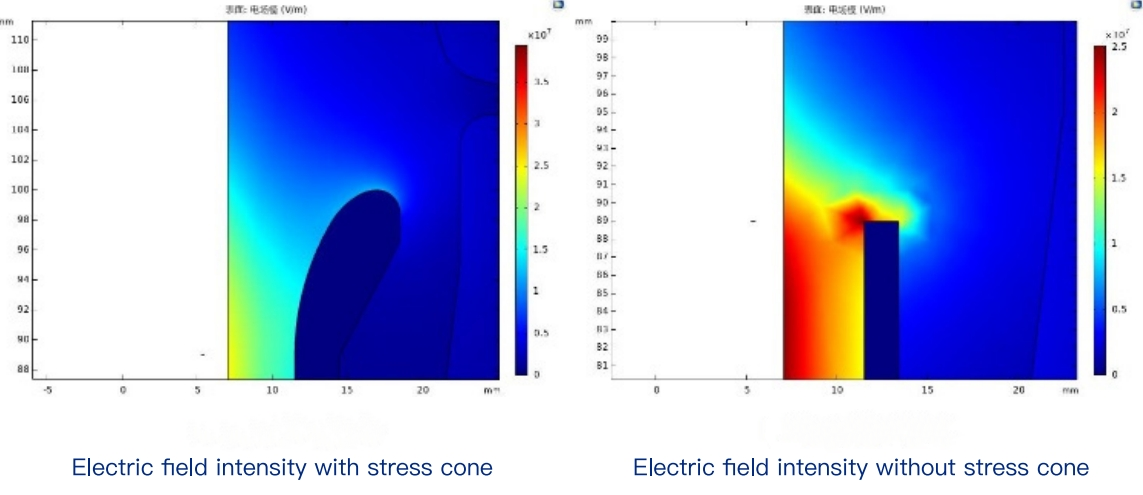

1.Optimize the structure of calculations (stress cone and conductive cube), and effectively reduce the electric field intensity at the cut-off point of cable shield.

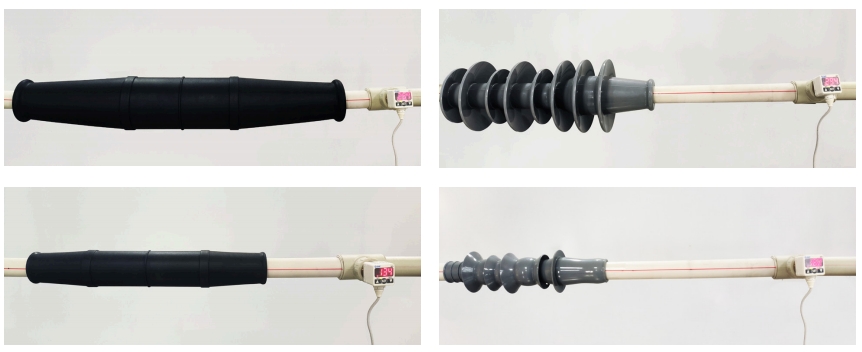

2.The rubber body has elastic memory and can maintain a lasting holding force.

| Holding Force Test Sheet | |||||

| Electric Voltage | Name | Pressure Gauge MPa | Electric Voltage | Name | Pressure Gauge MPa |

| 35kV | Intermediate Joint | 257 | 10kV | Intermediate Joint | 134 |

| Terminal | 294 | Terminal | 148 | ||

| Terminal | 182 | ||||

1.Prefabrication molding: under the environment and process conditions strictly controlled by the factory, the electrical stress processing unit required by the operation of cable accessories and the reinforced insulation mold are made into a whole.

2.Pre-expansion technology: making use of the "elastic memory" characteristic of rubber material, pre-expand the elastic rubber in its elastic range and insert plastic lining strip for fixation. During installation, just pull out the lining strip, the elastomer will contract quickly and clamp to the cable tightly.