We offer OEM/ODM service and prioritize delivering high-quality products in a timely manner. Join us as our partner today!

Independent brand, free factory: We have full creative control and ownership of our manufacturing facilities.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

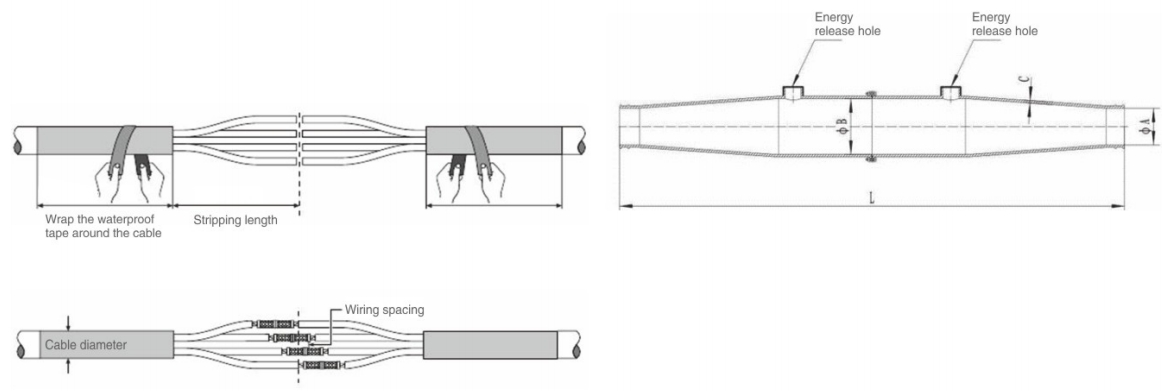

This series of products is suitable for waterproofing,fireproofing, explosion-proof and direct burial with stand voltage protection of cold and hot shrink intermediate joints of cross-linked polyethylene insulated power cable with a nominal cross-section of 50 to 630mm².

This product is molded with unsaturated resin (or SMC)and high strength glass fiber, which has tough physical properties, can avoid power being damaged by external forces, and can effectively prevent the shock wave and flame generated by the explosion in the event of smoke and combustion accidents in the power intermediate joint to avoid secondary disasters.

|

Experimental projects |

Inspection site | Inspection content | Judgement | Standard |

| Structural inspection | The whole machine | 1)The nameplate mark complies with the standards;2)The structural dimensions comply with the drawings and standards;3)Creepage distance and electrical clearance meet standards. | Qualified | GB3836.1-2010 GB3836.3-2010 relevant requirements |

| Introduction device clamping performance test | Introduction device | A tensile force of 680N is applied to a cable with a diameter of 34mm for 6h, and no displacement occurs. | Qualified | GB3636.1-2010 appendix A.3 |

| Impact test | Shell | The housing bears the impact energy generated by the vertical fall of a test object with a mass of 1.0 kg from 0.7m, and there is no damage. | Qualified | GB3836.1-2010 article 26.4.2 |

| Aging resistance test | Seal gasket/Cement/Joint glue sealing part | The samples are placed in an environment of humidity: 90% and temperature: 95'℃ for 14 days, and then placed in an environment of 126'℃ for 14 days; They are placed at room temperature for 24h,and then placed at -30'℃ for 1 day; After the test, there is no obvious change in the sealing ring, cement and where the joint is sealed. | Qualified | GB3836.1-2010 article 26.8、26.9 and appendix A.3 |

| Shell protection experiment | The whole machine | Level 5 dustproof: the sample is placed in a dustproof box and the negative pressure of pumping is 2kpa, and after 2h, there is no dust accumulation in the product shell;Level 5 waterproof: At 3m away from the sample, the spray gun with a water consumption of 12.5L/min sprays water on the sample for3min, and no water enters the product shell. | Qualified | GB4208-2008 |

| Experimental projects | Inspection site | Inspection content | Judgement | Standard |

| Temperature experiment | Shell/At the joint/Glue sealing part |

The maximum surface temperatures of the sample shell, joint and cable joint glue sealing part are 49.4℃,107.8 ℃ and 105.9℃ respectively. Note: The cross-section area of the test cable is 240mm. |

Qualified | GB3836.1-2010 article 26.5.1 |

| Dielectric constant | Relative | Test voltage:21000V;Experiment time: 60S; Experimental results:no breakdown, no arcing, no flashover. | Qualified | GB3836.1 appendix A.3 |

| Surface resistivity | Sample | The experimental results show that the surface resistance value of the sample is 7.69*10^8Ω. | Qualified | GB3836.1/26.13 |

| Flame retardant | Shell/Seal gasket | According to Article 9 of GB/T 5169.16-2008, the combustion level of the vertical combustion test is V-0, so the combustion performance level conforms to B1. | Qualified | GB8624-2012 |