We offer OEM/ODM service and prioritize delivering high-quality products in a timely manner. Join us as our partner today!

Independent brand, free factory: We have full creative control and ownership of our manufacturing facilities.

One-stop service, turnkey project service: We provide end-to-end solutions, managing every aspect of projects from start to finish.

Design team, technical team: Our experts in design and technology collaborate to deliver innovative and meticulously crafted products.

En50181-1997 1kV to 36kV and 250A to 1.25kA plug-in bushings for equipment excluding liquid filled transformers.

DlN47636 Power cable socket assembly accessories for external cone shaped instrument connectorslEC60502 Extruded insulated power cables and their accessories with rated voltages ranging from 1kV(Um=1.2kV)to 30kV(Um=36kV)lEC61 442 Testing methods of power cable accessories with rated voltages ranging from 6kV (Um=7.2kV)to 30kV(Um=36kV)

GB12706-2008 Extruded insulated power cables and their accessories with rated voltages ranging from1kV(Um=1.2kV)to 35kV(Um=40.5kV)GB31 1.1-1997 Insulation coordination of high-voltage transmission and distribution equipmentGB/T4109-1999 Technical specification of high voltage bushingGB11032-2000 Altemating current metal-oxide arrester without gaps

The 10kV European type front connector is used in 10kV cable distribution boxes, ring network cabinets, inflatable cabinets and high-voltage switchgear, directly installed on the equipment casing, used for inlet and outlet cable connection and sealing. The product adopts the international advanced post-injection insulation layer process, and the electrical performance has reached the international leading level, which makes it be safer and more reliable to use. The installation is not affected by harsh environmental. The stress treatment of the product adopts international advanced technology. lts structure size is small, which fully meets the requirements of installation space, and it is the leading prefabricated electric head in the world. lt is suitable for the cable whose cross-section is 25-630m㎡.

| Voltage grade | 10kV |

| Rated voltage | 15kV |

| Rated current | 630A |

| 1 minute A.C withstand voltage | 42kV |

| 15 minutes DC withstand voltage | 52kV |

| Lightning impulse withstand voltage | 95kV |

| Minimum corona onset voltage | 11kV |

| Thermal short-circuit current | 22.8kA/2S |

| Dynamic short-circuit current | 80.8kA |

| Partial discharge | ≤10pC |

The 10kV European type rear connector is used in 10kV cable distribution boxes, ring network cabinets, inflatable cabinets and high-voltage switchgear, directly installed behind the front connector, The product adopts the international advanced post-injection insulation layer process, and the electrical performance has reached the international leading level, which makes it be safer and more reliable to use. The installation is not affected by harsh environmental.The stress treatment of the product adopts international advanced technology. its structure size is small, which fully meets the requirements of installation space, and it is the leading prefabricated electric head in the world. lt is suitable for the cable whose cross-section is 25-630m㎡.

The 10kV rear arrester is installed behind the front and rear joints of the ring network cabinets, inflatable cabinets, distribution boxes and high-voltage switchgear. lt can provide reliable over voltage protection for electrical systems. The outer semi-conductive layer of the shielded arrester ensures the personal safety of the installation and maintenance personnel and the safe operation of the equipment, and the unique properties of waterproofing and moisture-proof ensure the safe and reliable operation of the product in the harsh environment.

| Parameters | 17/45 | 17/50 |

| Rated voltage | 17kV | |

| Continuous operation voltage | 13.6kV | |

| Lightning impulse residual voltage |

≤45kV |

≤50kV |

| at D.C.1 mA reference voltage U1mA |

≥24.0kV |

≥26.0kV |

| Leaking current at D.C.0.75 U1mA |

≤30μA |

|

| 2000us Rectangular current | ≥200kV | ≥100kV |

| 4/10usHigh current impulse withstand voltage | ≥65kV | |

| 1.05UcPartial discharge | ≤10PC | |

| A.C.withstand voltage test for EPDM housing | 42kV/1min | |

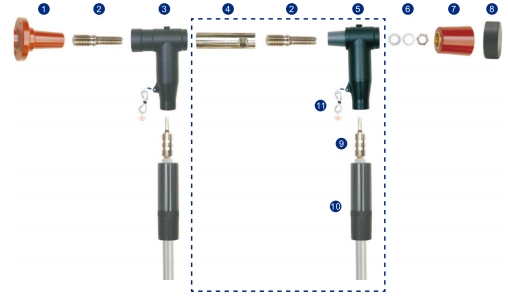

Front connector and rear connector (rear connected arrester)

Assembly sequence schematic (rear connector for repeated installation of multiple branches)

1.Connected casing 2.M16/M12*65stud 3.Front connector(front connector arrester) 4.Connecting rod 5.Rear connector(rear connector arrester) 6.Flat pad,bounce pad,nut 7.Insulating plug 8.Conductive cap 9.Terminal block 10.Stress cone 11.Ground wire

The 35kV 630A shielded front connector is suitable for power plants with power frequency AC voltage of 35kV and below, power distribution and high-voltage electricity, such as: electrical connectors, closer, charging wind power entry and exit of GlS system. The product adopts the international advanced backward injection insulation layer process, and the electrical performance has reached the international leading level, which makes it safer and more reliable to use. The installation conditions are not affected by the environment. The stress treatment of the product adopts international advanced technology. its structure size is small, which fully meets the requirements of installation space, and it is the leading prefabricated electric head in the world. lt is suitable for the cable whose cross-section is 50-500m㎡.

| Voltage grade | 35kV |

| Rated voltage | 40.5kV |

| Rated current | 630A |

| 1 minute A.C withstand voltage | 95kV |

| 15 minutes DC withstand voltage | 117kV |

| Lightning impulse withstand voltage | 185kV |

| Minimum corona onset voltage | 26kV |

| The short-time withstand current | 27kA/3S 40kA/0.2S |

| Partial discharge | ≤10pC |

The 35kV 630A shielded cable rear connector is connected behind the front connector, and a rear connector or rear arrester can also be installed behind the rear connector to achieve multi-circuit in coming and outgoing line configuration. lt is suitable for power plants with a power frequency AC voltage of 35kV and below, distribution units for power transformation and high voltage electricity. The product uses the international advanced trailing edge layer technology. The electrical performance has reached the international leading level, and the use is safer and more reliable. The installation conditions are not affected by the environment. The product adopts international advanced technology,its structure size is small, which fully meets the requirements of installation space, and it is the leading prefabricated electric head in the world. lt is suitable for the cable whose cross-section is 50-500m㎡.

The 35kV rear arrester is installed behind the front and rear joints of the ring network cabinets, inflatable cabinets, distribution boxes and high-voltage switchgear. lt can provide reliable over voltage protection for electrical systems. The outer semi-conductive layer of the shielded arrester ensures the personal safety of the installation and maintenance personnel and the safe operation of the equipment, and the unique properties of waterproofing and moisture-proof ensure the safe and reliable operation of the product in the harsh environment.

| Parameters | 51/134 |

| Rated voltage | 51kV |

| Continuous operation voltage | 40.5kV |

| Lightning impulse residual voltage | ≤134kV |

| at D.C.1 mA reference voltage U1mA | ≥73.0kV |

| Leaking current at D.C.0.75 U1mA | <50μA |

| 2000μs Rectangular current | =400A |

| 4/10μsHigh current impulse withstand voltage | ≥65kV |

| 1.05UcPartial discharge | ≤10pC |

| A.C.withstand voltage test for EPDM housing | 95kV/1min |