Introduction

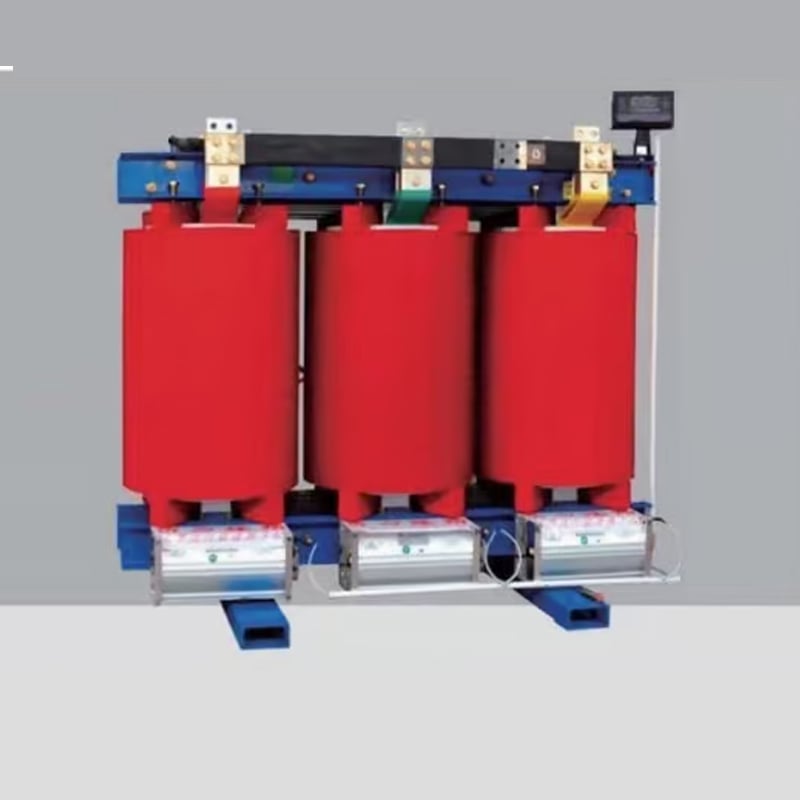

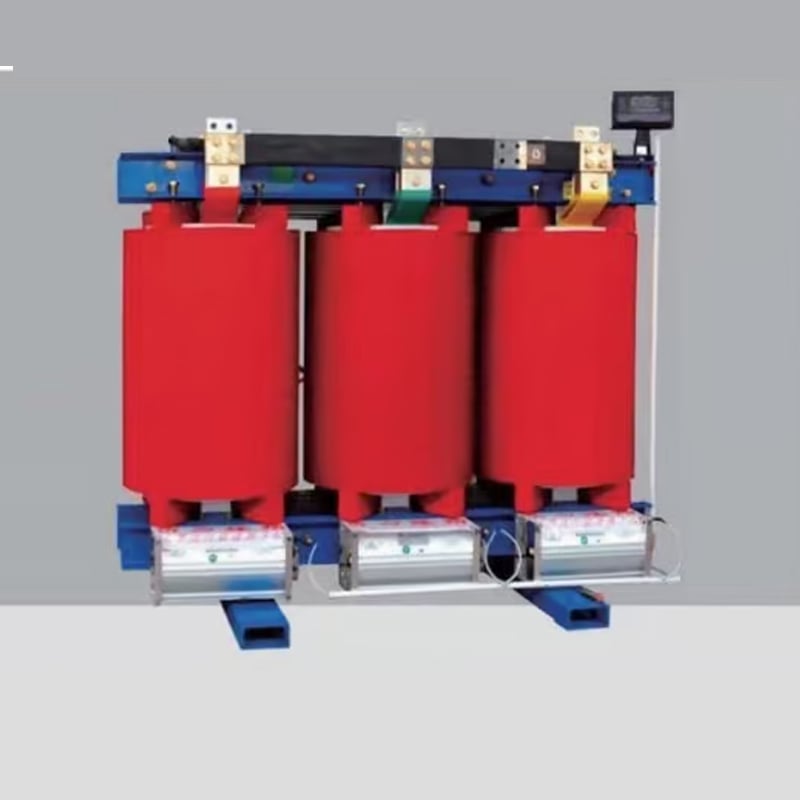

Have you ever wondered why dry transformers are becoming more popular in the electrical industry? You may have heard about them, but what makes them so unique? In this article, we'll explore the advantages of using a dry transformer and why they're a great option for many different scenarios.

1. Safety

One of the biggest advantages of dry transformers is their safety. Unlike oil-filled transformers, dry transformers don't use flammable liquid insulation. This makes them ideal for locations where fire safety is a concern, such as hospitals, schools, and high-rise buildings.

2. Low Maintenance

Dry transformers require minimal maintenance compared to their oil-filled counterparts. Since they don't have oil, there's less chance of leaks, which can be costly to repair. In addition, dry transformers don't require regular oil analysis or oil changes, which can save time and money in the long run.

3. Environmental Concerns

Dry transformers are eco-friendly. As mentioned, they don't require oil, which means they don't contribute to oil spills or soil contamination. This makes them a great option for companies that want to reduce their carbon footprint.

4. Better Performance

Dry transformers are known for their high performance. They have a higher thermal conductivity, which means they can handle higher loads without overheating. Additionally, dry transformers can operate at higher temperatures and maintain their efficiency, which allows for more reliable operation.

5. Cost-Effective

Dry transformers are generally less expensive than oil-filled transformers. While the initial cost may be higher, the savings in maintenance costs over time often make up for it. In addition, dry transformers are smaller and lighter than oil-filled transformers, which can also save on installation costs.

6. Durability

Dry transformers can withstand harsh environments. They're able to handle extreme temperatures, vibration, and moisture without degrading. This makes them ideal for industrial applications, such as mining or manufacturing, where the environment can be tough on electrical equipment.

7. Reduced Fire Risk

Since dry transformers don't use oil, the risk of fire is greatly reduced. This is particularly important in locations where fire safety is a concern, such as schools, hospitals, and other public buildings. It also means that there's less need for fire suppression systems, which can be costly to install and maintain.

8. Noise Reduction

Dry transformers are quieter than oil-filled transformers. This makes them a great option for locations where noise levels need to be kept to a minimum, such as residential areas or public places.

9. Customization

Dry transformers can be customized to meet specific requirements. They can be designed to fit in tight spaces, handle specific loads, or work with different voltages. This makes them versatile and adaptable to different applications.

10. Low Risk of Contamination

Finally, dry transformers are less likely to become contaminated. Oil-filled transformers can be contaminated by water, dust, or other debris, which can affect their performance. Dry transformers don't have this issue, which means they can maintain their efficiency over time.

dry transformer, advantages, safety, low maintenance, eco-friendly, performance, cost-effective, durability, fire risk, noise reduction, customization, low risk of contamination

Why would you use a dry transformer?? Key Advantages Explained

Discover the advantages of using dry transformers including safety, low maintenance, eco-friendliness, better performance, cost-effectiveness, noise reduction, customization, and more. Find out more here.

Quote Inquiry

Contact Us Now!