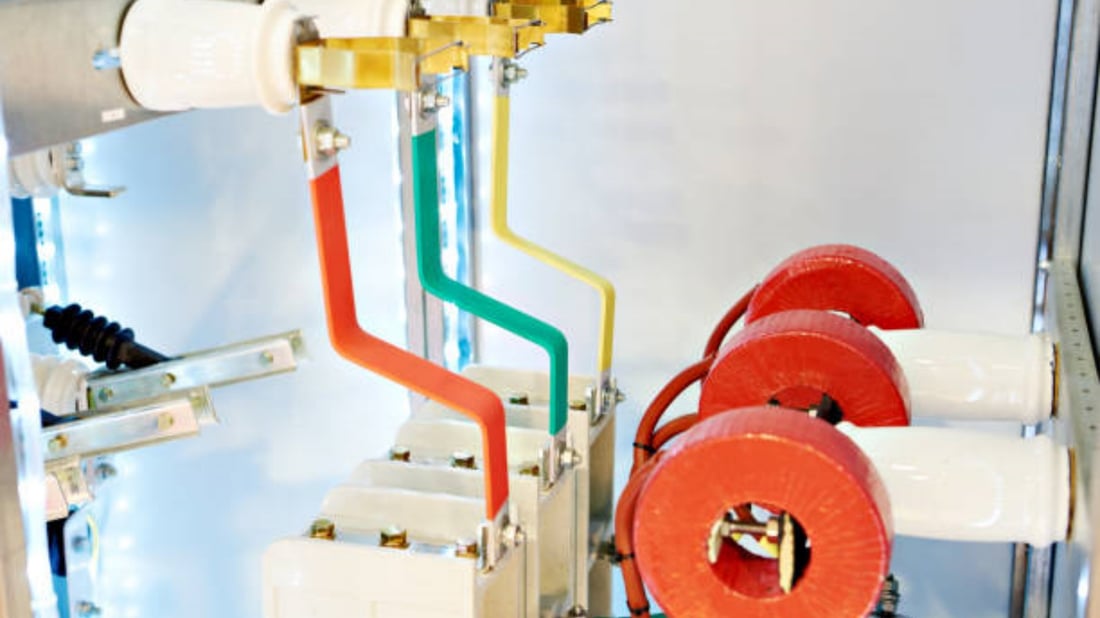

Understanding the Importance of Busbar Protective Covers

Busbar protective covers play a critical role in electrical systems by providing insulation and safeguarding against accidental contact with live busbars. These covers help prevent electrical shocks, short circuits, and equipment damage. Recognizing the importance of periodic busbar protective cover replacement ensures electrical safety and system reliability. Regular maintenance and timely replacement of worn covers reduce risks associated with electrical faults.

When to Consider Busbar Protective Cover Replacement

Identifying signs that indicate the need for busbar protective cover replacement is essential for electrical safety professionals. Visible cracks, discoloration, brittleness, or deformation are common signs that the protective cover has deteriorated. Additionally, covers that no longer fit securely or have been exposed to excessive heat or chemical damage should be replaced promptly to maintain system integrity.

Essential Tools and Safety Precautions for Replacement

Before starting the

Busbar Protective Cover Replacement Steps, it’s important to gather the right tools such as insulated gloves, screwdrivers, multimeters, and replacement covers. Strict adherence to safety precautions is necessary, including isolating the electrical supply, verifying zero voltage with appropriate testing devices, and wearing proper personal protective equipment (PPE) to prevent electric shock during replacement.

Preparing the Work Area for Replacement

Preparation is a crucial step in the busbar protective cover replacement process. Clearing the area around the busbar, ensuring good lighting, and securing nearby components enhance safety and efficiency. Establishing barriers or warning signs to restrict unauthorized access while replacement is underway minimizes hazards to staff and helps maintain a controlled environment.

Step-by-Step Removal of the Old Busbar Protective Cover

Proper removal of the old protective cover involves methodical steps to avoid damage to the busbar and surrounding components. Begin by loosening any screws or fasteners that secure the cover. Gently lift or slide the cover away from the busbar, taking care not to apply excessive force that could dislodge or deform the busbar or insulation beneath.

Inspection of Busbar Condition Before Installing New Cover

Once the old protective cover is removed, conducting a thorough inspection of the busbar is vital. Look for signs of corrosion, heat damage, or physical deformities. Cleaning the busbar surface of dust, grease, or debris improves the fit and effectiveness of the replacement cover. Addressing any issues found during inspection can prevent future failures.

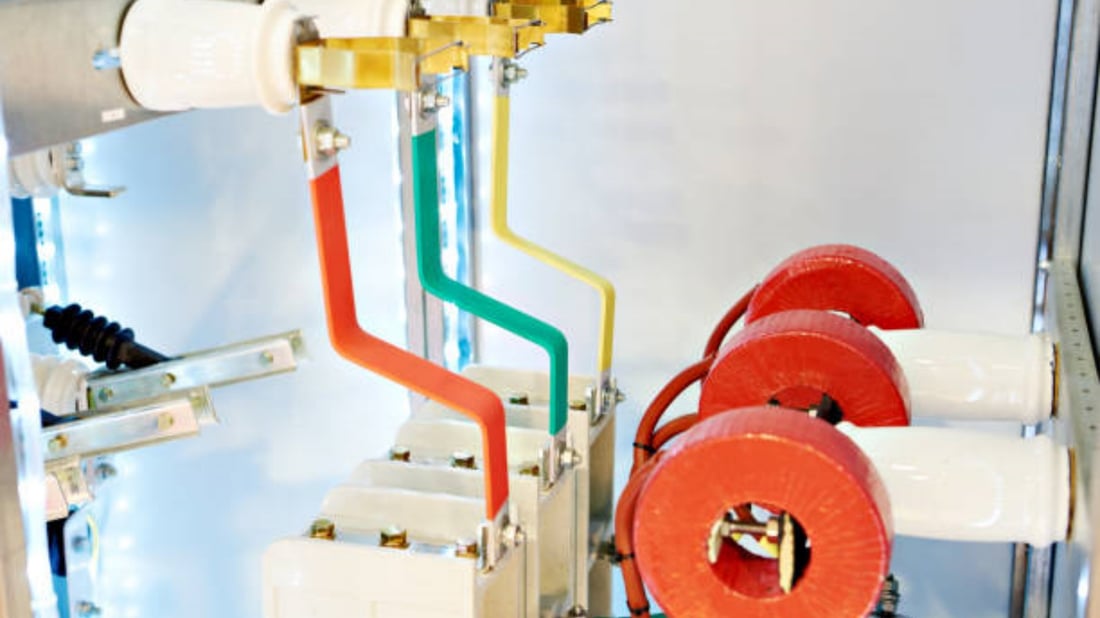

Selecting the Right Replacement Busbar Protective Cover

Choosing the appropriate replacement cover requires consideration of material compatibility, insulation rating, and size specifications. Covers made from high-quality, heat-resistant insulating materials provide better durability and safety. Ensuring the new cover matches the dimensions and mounting style of the original cover simplifies installation and guarantees secure protection.

Installing the New Busbar Protective Cover Correctly

Installation is performed by aligning the new cover properly over the busbar and securing it with screws, clamps, or locking mechanisms as per manufacturer instructions. Verify that the cover fits snugly without gaps and does not interfere with adjacent electrical components. Proper installation is key to maintaining electrical safety and protecting against accidental contact.

Post-Replacement Testing and Safety Verification

After replacing the busbar protective cover, conducting safety checks is necessary to confirm proper installation. Testing for insulation continuity, using a multimeter, and ensuring that all fasteners are tightened secures the replacement. Additionally, re-energize the system carefully and verify that there are no unusual noises, smells, or overheating around the busbar area.

Maintenance Tips to Extend Busbar Protective Cover Life

Routine maintenance prolongs the life of busbar protective covers and enhances electrical safety. Regular cleaning, visual inspections for signs of wear, and avoiding exposure to harsh chemicals or excessive heat preserve cover integrity. Establishing a maintenance schedule aligned with operational demands helps detect issues early and ensures timely busbar protective cover replacement steps are performed when necessary.

Quote Inquiry

contact us